EV chargers

Power Electronics for DC Fast Chargers

Customer service

Product service

Performance Range

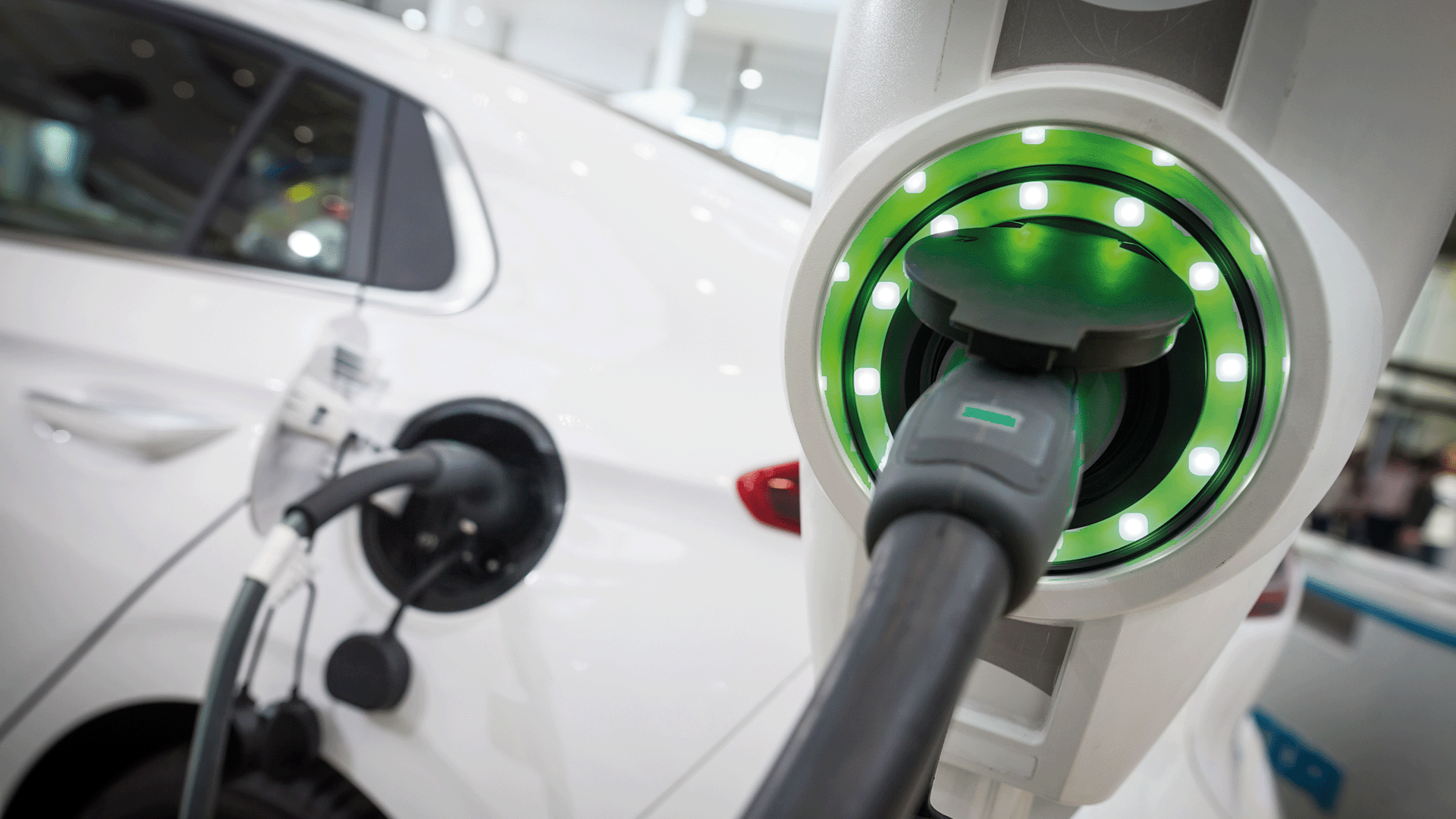

As electric vehicles become widespread, so must the infrastructure to charge them. One of the main requirements for the widespread use of electric vehicles is an accessible EV charging infrastructure. Governments and industries worldwide are investing in charging infrastructures, with a growing trend toward bidirectional charging.

Availability and costs are the key to success in the fast growing EV Charger market. As the specialist in power electronics, we use state-of-the-art topologies featuring standard components, guaranteeing both excellent efficiency and availability. SEMIKRON Danfoss offers a comprehensive portfolio of products that meet the needs of fast charge equipment from as little as 8kW up to the megawatt range.

Product Highlights

Industrial Standard Combined with Superior Performance

DC Fast Chargers require a power dense PFC, DC/DC, and output rectifier, all available in the SEMITOP E1/E2 packages. With a low inductance design, fast switching Si and SiC chips may be used to their full potential. Achieve supply chain safety with this industrial standard module in a wide array of topologies.

Key Features

- Low inductance package

- Multiple sourcing down to chip level

- Optimized footprint

- Flexible architecture

- 2-screw concept

- Press-Fit terminals

- 12mm module height

- No baseplate

The thermal resistance is up 20% lower than the closest competitor using standard thermal paste. Using High Performance Thermal Paste (HPTP), a further 25% reduction is possible.

More about SEMITOP E1/E2The Ultimate Partner for Silicon Carbide Power Modules

For power dense EV chargers, silicon carbide enables freedom of design for today's power electronics. Silicon carbide exhibits extremely low switching losses which yield less cooling effort and higher efficiency. The result is smaller, lighter power converters and reduced energy usage.

The industry standard SEMITOP E1 and E2 feature high thermal performance and low stray inductance. Standart pinout configurations allow for multiple sourcing to ensure supply chain safety.

Key Features

- Fast switching SiC reduces lasses, simplifying cooling effect

- Multiple chip sources for improved supply chain safety

- Matrix hale pattern for flexible topologies and law inductance

- 3-level TNPC topology enables reduced magnetics size and cost

Power Electronic Stack Platforms

Fully Qualified Inverter Assemblies Tailored to Your Specific Needs

Standard Stacks

Our Power Electronic Stacks enable our costumers to succeed in dynamic markets and meet any global challenge. We deliver Rectifier-, IGBT- and SiC-based stacks for AC voltages from 380V to 690V. Our standard stacks cover an output current range from 70A to 4000A.

- Water Cooled IGBT Stacks

SEMISTACK RE

SEMIKUBE MLI - Air Cooled IGBT Stacks

SEMIKUBES

SEMIKUBE SlimLine - Diode/Thyristor Stacks

SEMISTACK CLASSIC B6U/B6C/W3C

Customized Stacks

In addition to standard stacks, SEMIKRON Danfoss has vast experience in developing customer-specific solutions. Engineers are available in our stack centres around the globe to offer such solutions by adapting existing platforms or designing customized converters.

Four Key Factors for Your success:

- Shortest time to market

- Cost savings in R&D, production and qualification

- Global SEMIKRON Danfoss stack production footprint

- Highly experienced engineering team

Thermal Interface Materials

Stay Cool - Heat Dissipation is Our Job

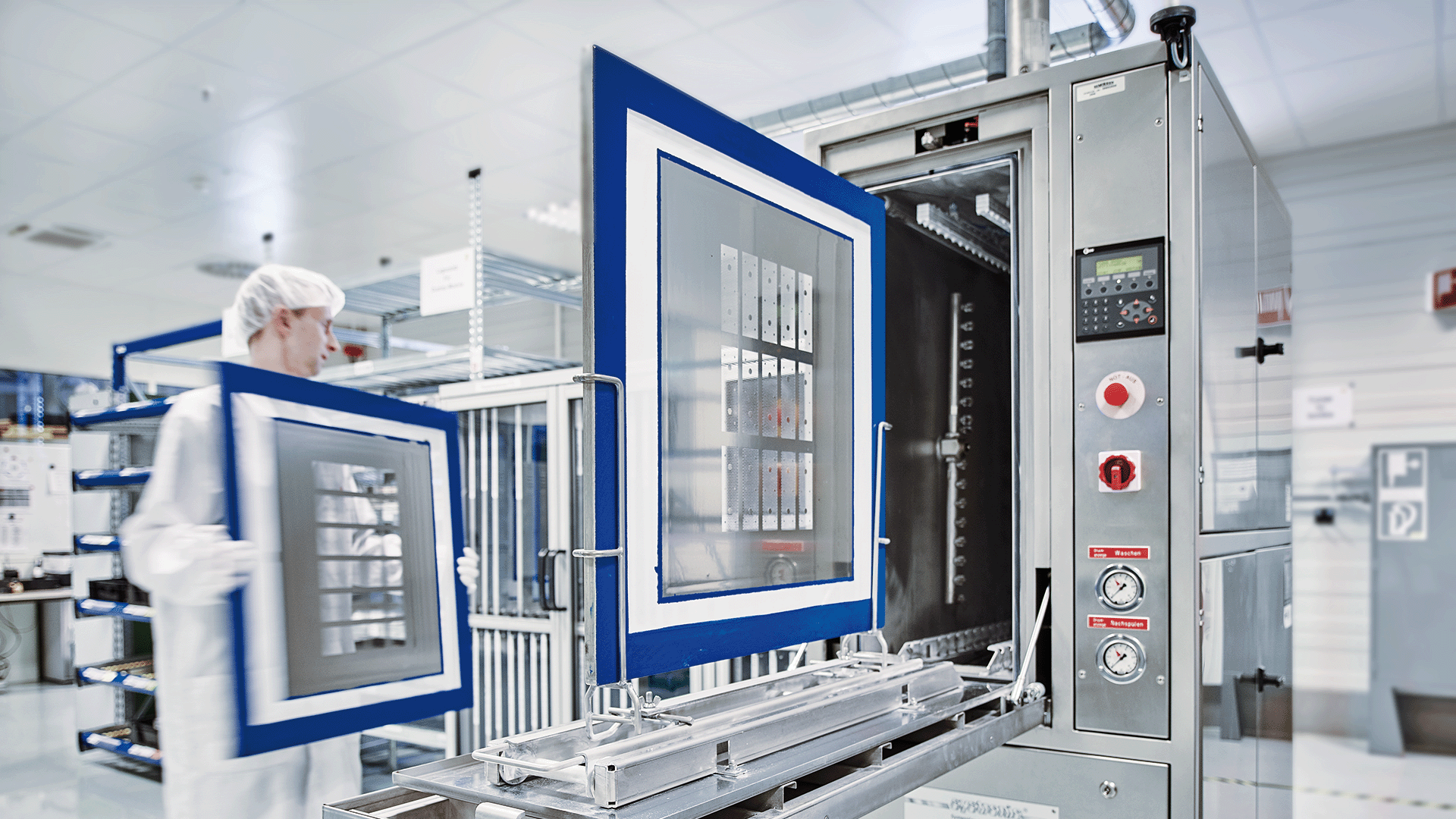

Semikron Danfoss was the first power module manufacturer on the market to offer power modules with pre-applied thermal interface material (TIM). We now have over two decades of experience and more than 25 million pre-printed modules in the field.

We design print patterns for each module type for the best TIM distribution and thickness when the module is mounted to a heatsink. These patterns are printed on the modules in a clean environment on an automated silkscreen and stencil printing line. Statistical process control (SPC) is used to guarantee consistency. Special packaging is implemented to ensure that the TIM arrives at your production line in pristine condition.

In order to achieve the best thermal performance in all applications, Semikron Danfoss power modules can be supplied with our High Performance Thermal Paste (HPTP).

Alternatively, for ease-of-handing during assembly, most power modules are also available with pre-applied phase change material (PCM). Phase change materials have a solid consistency at room temperature. With the application of heat during first operation, the PCM flows to fill gaps and provide a thermal interface. With HP-PCM, the new Semikron Danfoss-exclusive High Performance Phase Change Material, we combine the benefits of a phase change material with the performance of the best available paste.

Key Features

- Best possible thermal performance

- Simplified logistics and reduced production costs

- Improved assembly robustness

- Increased lifetime and reliability

Portfolio

- HPTP: High Performance Thermal Paste

- HP-PCM: High Performance Phase Change Material