Rail Traction Systems

Power Electronics for Traction Applications

Downloads

Customer service

Product service

Performance Range

Whenever we talk about traction applications, we see extremely high demand for reliability, lifetime and safety. Semikron Danfoss is offering this requirements to our customers since we developed the first isolated power module on the market in 1974. For more than 25 years, our highly reliable SKiiP IPMs are driving light rails, trams and subways all over the world.

With our new SEMITRANS 20 power module family, Semikron Danfoss brings latest sinter and bonding technology to the new high power standard package. Semikron Danfoss also stands for innovative solutions for auxiliary power supplies: our silicon and silicon carbide powered devices, especially the SEMITRANS and SEMITOP module families, allow reliable, efficient and compact systems.

- AUXILIARY POWER SUPPLY5kW - 500kW

- Compact designs and high power density

- High reliability in harsh environments

- High power quality

- High efficiency

- MAIN TRACTION DRIVE500kW - 10MW

- Highest reliability and lifetime

- High power cycling capability

- Long lifetime and availability

Product Highlights

The New High Power Standard in Rail Traction Drives

The SEMITRANS 20 product family increases product lifetime and power output. SEMITRANS 20 modules deliver significant advantages for the traction market:

- A simplified inverter design leads to reduced costs for mounting materials as well as in the inverter assembly process

- More space for driver boards and less EMC disturbance from high current bus bars to the driver

- Three AC terminal connectors for low operating temperatures even at high loads

- Less de-rating at parallel operation thanks to the low inductance bus bar layout and the extremely low module inductance

- Ideal for cost-effective inverter design and scaling

On top of this, the SEMITRANS 20 Traction module provides Semikron Danfoss innovative technologies such as sintered chips and AlCu wire bonds. Additionally the SEMITRANS 20 Traction features silicon nitride (Si3N4) substrate and AlSiC baseplates to enable a higher isolation voltage of 6kV and lower partial discharge.

- Superior product lifetime

- Lower cost per kW

- Higher power density

Key Features

- Standard package for traction and industrial applications

- Innovative technologies with sintered chips and AlCu wire bonds

- Next level lifetime and power density

- Lower mounting and material cost in inverter assemblies

- Ideal for paralleling and scaling

SiC and Hybrid SiC modules for Auxiliary Power Supplies

The SEMITRANS 3 product family is growing with its new full and hybrid SiC half-bridge modules in 1200V and 1700V. This new portfolio extension allows highly efficient auxiliary power supplies. Due to the high switching frequency of the silicon carbide devices, the size of the passive components can be reduced, and inaudible to the human ear, allowing reduced acoustic insulation.

The decreased losses reduce service and maintenance costs, thanks to passive cooling of the power electronic components. Multiple sourcing down to chip level ensures maximum supply chain safety. Available in 1200V from 350A to 500A and in 1700V from 260A to 400A.

Benefits of SiC Technology in Auxiliary Power Supplies

- High switching frequencies >20kHz are not audible by human ear

- Low switching losses allow natural cooling for reduced maintenance

- Dramatically reduced filter size thanks to high switching frequencies

- Dramatically reduced transformer size of DC/DC converters

- Smaller total size and volume of complete auxiliary converter

Intelligent Power Modules – IPMs

For Maximum Reliability

The SKiiP IPM product line sets a benchmark for high performance and robust inverter designs. Both SKiiP 3 and SKiiP 4 feature high power densities combined with flexible cooling options such as air- or water cooling, also with customized heat sinks. Reliable driver technology, integrated current sensors and comprehensive protection functions complete the IPM design.

SKiiP 3 has propagated widely through the industrial drive segment. With its sixpack or half-bridge topologies, it covers a current range from 500A up to 2400A.

Key Features

- 1200V and 1700V

- Half-bridge and sixpack

- 500A to 3600A

- Flexible cooling options: air, water or customized cooling options, high performance cooling, single and double side mounting water coolers

- Paralleled operation for even higher output power possible

- Special version for 1500VDC available

- Not valid for 1500VDC traction

The SKiiP 4, available in half-bridge topology, has been optimized for highest power cycling requirements and covers the higher power range up to 3600A.

To ensure highest reliability and service life, the power circuitry is 100% solder-free. Sinter technology as die attach replaces the solder layer, which usually causes the limitation in lifetime. Hence, sintering improves power and thermal cycling capability.

The integrated gate driver in the SKiiP 4 has set new standards in terms of reliability and enhanced functionality through its CAN interface. The digital driver guarantees safe isolation between the primary and secondary side for both switching signals and parameter measurement. The CAN interface allows setting the SKiiP 4 configuration parameter and reading application parameter.

High Performance Cooling (HPC) technology has been introduced providing approximately 25% more output capability compared to standard water cooling. A double side mounting HPC water cooler is also available and enables an even higher power density.

More about SKiiP

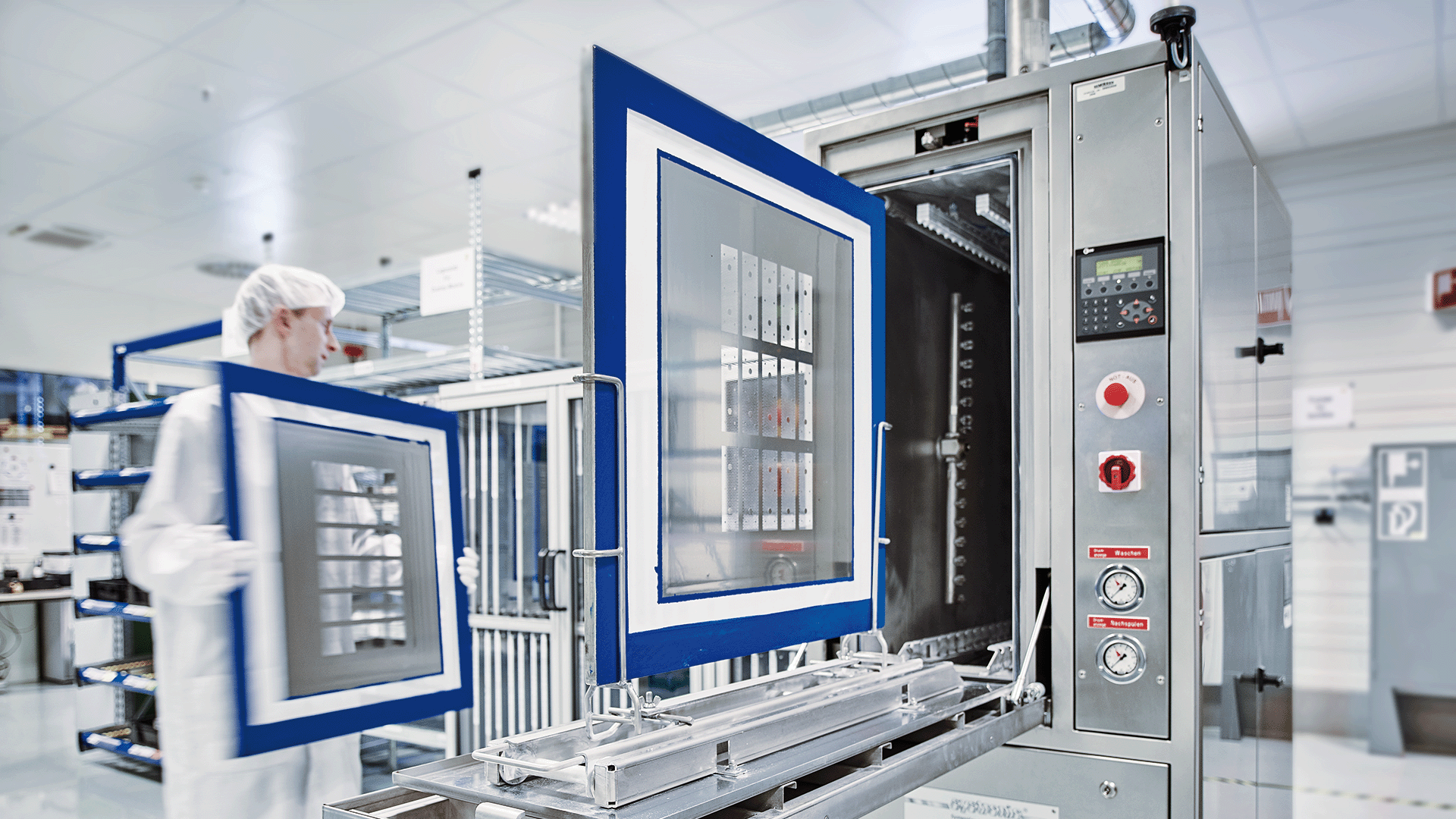

Thermal Interface Materials (TIM)

Stay Cool - Heat Dissipation is Our Job

Semikron Danfoss was the first power module manufacturer on the market to offer power modules with pre-applied thermal interface material (TIM). We now have over two decades of experience and more than 25 million pre-printed modules in the field.

We design print patterns for each module type for the best TIM distribution and thickness when the module is mounted to a heatsink. These patterns are printed on the modules in a clean environment on an automated silkscreen and stencil printing line. Statistical process control (SPC) is used to guarantee consistency. Special packaging is implemented to ensure that the TIM arrives at your production line in pristine condition.

In order to achieve the best thermal performance in all applications, Semikron Danfoss power modules can be supplied with our High Performance Thermal Paste (HPTP).

Alternatively, for ease-of-handling during assembly, most power modules are also available with pre-applied phase change material (PCM). Phase change materials have a solid consistency at room temperature. With the application of heat during first operation, the PCM flows to fill gaps and provide a thermal interface. With HP-PCM, the new Semikron Danfoss-exclusive High Performance Phase Change Material, we combine the benefits of a phase change material with the performance of the best available paste.

Key Features

- Best possible thermal performance

- Simplified logistics and reduced production costs

- Improved assembly robustness

- Increased lifetime and reliability

Portfolio

- HPTP: High Performance Thermal Paste

- HP-PCM: High Performance Phase Change Material