UPS Systems

Power Electronics for UPS Systems

Customer service

Product service

Performance Range

The availability of infrastructure systems strongly depends on reliable power supplies, irrespective of whether these systems are servers and cloud storage systems, critical traffic control or hospital services.

Uninterruptable Power Supplies (UPS) ensure continuous operation of these critical systems. In Semikron Danfoss power modules, flexible topologies equipped with the latest IGBT and diode chips ensure maximum conversion efficiency for double conversion UPS systems. This efficiency can be further improved using silicon carbide technology.

- LOW POWER AND MODULAR UPS SYSTEMS10kVA - 125kVAServer rooms, Data centres

- High efficiency systems

- Compact designs and high power density

- STANDALONE AND TOWER UPS SYSTEMS100kVA - 5MVAServer rooms, Data centres, Hospitals and critical control systems

- High efficiency systems

- Compact designs and high power density

Product Highlights

High Power Density UPS

with a Classic Power Module

One of the main design targets for UPS systems is power density as installation space is costly. For medium to high power UPS systems, 3-level topologies like TNPC are a quasi standard. The SEMITRANS Classic TNPC fulfills both requirements and is the perfect choice for your medium power UPS system.

Thanks to the integration of the latest Generation 7 IGBTs, the SEMITRANS 3 TNPC increases power density significantly. Two modules form an efficient 3-level topology layout, scalable from 450 to 800A nominal current, allowing 200 to 300kVA output power respectively.

With silicon carbide MOSFET versions of the vertical half-bridge the output power density can be further increased. The pre-applied High Performance Phase Change Material gives it another boost.

Key Features

- High power density thanks to latest Generation 7 IGBTs

- Well-proven SEMITRANS Classic power module

- Designed for medium and high power building blocks up to 600kVA and parallel connection

- Further power density increase thanks to silicon carbide power module variants

Most Comprehensive UPS Portfolio

Highest UPS Power Density with SEMiX 5

With its comprehensive portfolio and its optimized design, the SEMiX 5 power modules are ideal for high-performance inverter architectures. The press-fit contacts ensure fast and solder-free driver board assembly, increased reliability and reduced assembly cost. An adapter board for easy gate drive integration is also available.

The internal chip layout is optimized for enhanced thermal performance, reducing operating temperatures and thus boosting reliability. The housing features rugged moulded power terminals for superior mechanical stability.

High power density thanks to comprehensive portfolio

- Biggest range of NPC and TNPC modules up to 400A nominal current

- Exceeding the standard: higher power density thanks to higher nominal currents in the same package

- Full range of symmetrical boost portfolio for input and battery charging

- Ready to use 3-level stack designs and application samples up to 500kW

Intelligent Power Modules – IPMs

The Most Powerful IPM in the Market

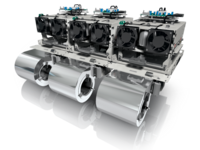

The SKiiP IPM product line sets a benchmark for high performance and robust inverter designs. Both SKiiP 3 and SKiiP 4 feature high power densities combined with flexible cooling options such as air or water cooling, also with customized heatsinks. Reliable driver technology, integrated current sensors and comprehensive protection functions complete the IPM design.

SKiiP 3 has propagated widely through the industrial drive segment. With its sixpack or half-bridge topologies, it covers a current range from 500A up to 2400A.

The SKiiP 4, available in half-bridge topology, has been optimized for highest power cycling requirements and covers the higher power range up to 3600A.

To ensure highest reliability and service life, the power circuitry is 100% solder-free. Sinter technology as die attach replaces the solder layer, which usually causes the limitation in lifetime. Hence, sintering improves power and thermal cycling capability.

The integrated gate driver in the SKiiP 4 has set new standards in terms of reliability and enhanced functionality through its CAN interface. The digital driver guarantees safe isolation between the primary and secondary side for both switching signals and parameter measurement. The CAN interface allows setting the SKiiP 4 configuration parameter and reading application parameter.

Key Features

- 1200V and 1700V

- Half-bridge and sixpacks

- 500A to 3600A

- Flexible cooling options: air, water or customized cooling options

- Paralleled operation for even higher output power possible

Power Electronic Stack Platforms

Fully Qualified Inverter Assemblies Tailored to Your Specific Needs

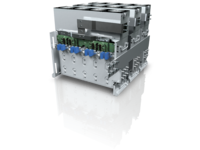

Standard Stacks

The Power Electronic Stacks enable our customers to succeed in dynamic markets and meet any global challenge. We deliver Rectifier-, IGBT- and SiC-based stacks for AC voltages from 380V to 690V. Our standard stacks cover an output current range from 70A to 4000A.

- Water Cooled IGBT Stacks

SKiiPRACK - Air Cooled IGBT Stacks

SEMIKUBE

SEMIKUBE SlimLine - Diode/Thyristor Stacks

SEMISTACK CLASSIC B6U/B6C/W3C

Customized stacks

In addition to standard stacks, Semikron Danfoss has vast experience in developing customer-specific solutions. Engineers are available in our stack centers around the globe to offer specific solutions by adapting existing platforms or designing customized converters.

Four Key Factors for your success

- Shortest time to market

- Cost savings in R&D, production and qualification

- Global Semikron Danfoss stack production footprint

- Highly experienced engineering team

Thermal Interface Materials

Stay Cool – Heat Dissipation is Our Job

Semikron Danfoss was the first power module manufacturer on the market to offer power modules with pre-applied thermal interface material (TIM). We now have over two decades of experience and more than 25 million pre-printed modules in the field.

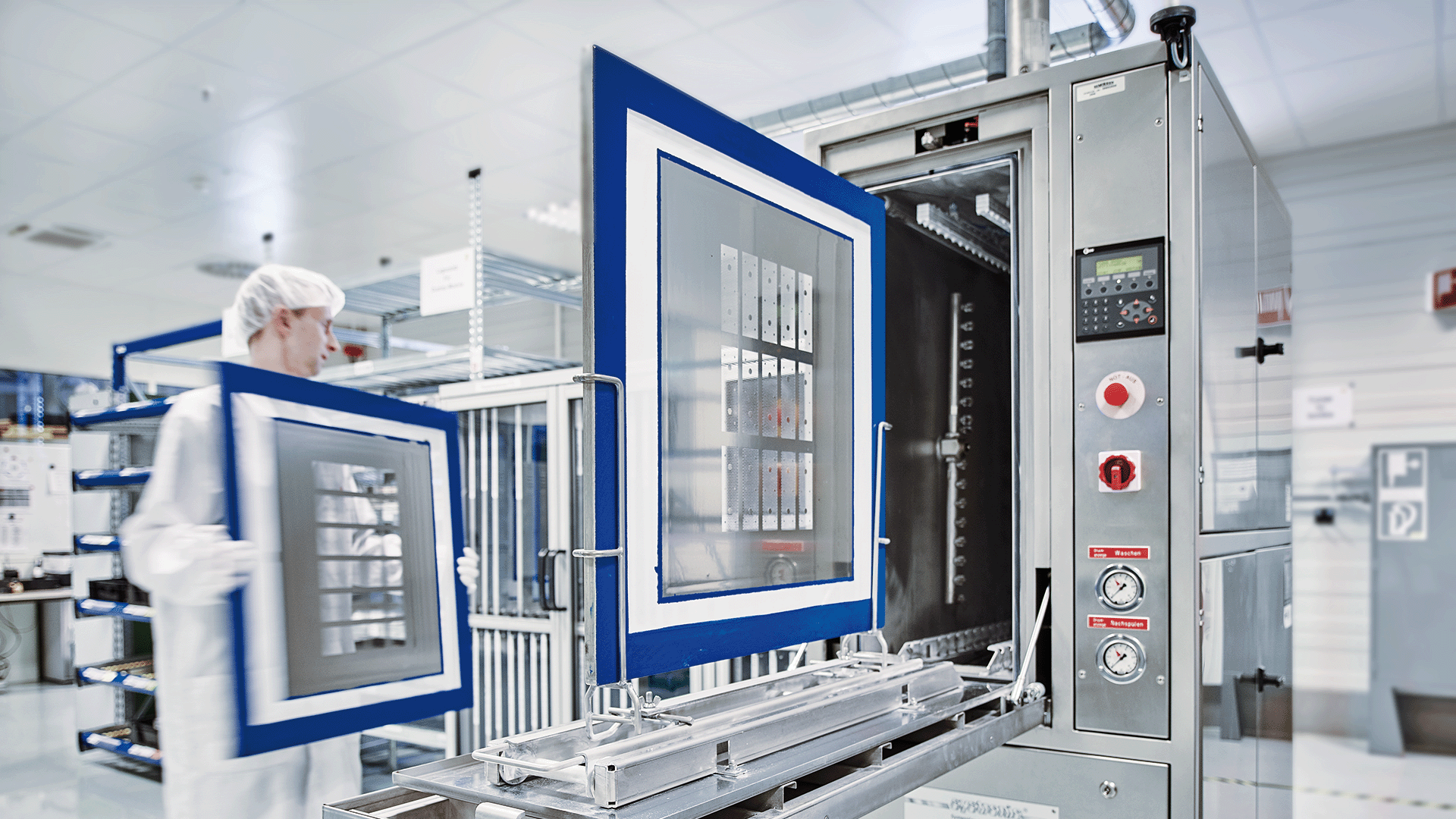

We design print patterns for each module type for the best TIM distribution and thickness when the module is mounted to a heatsink. These patterns are printed on the modules in a clean environment on an automated silkscreen and stencil printing line. Statistical process control (SPC) is used to guarantee consistency. Special packaging is implemented to ensure that the TIM arrives at your production line in pristine condition.

In order to achieve the best thermal performance in all applications, Semikron Danfoss power modules can be supplied with our High Performance Thermal Paste (HPTP).

Alternatively, for ease-of-handling during assembly, most power modules are also available with pre-applied phase change material (PCM). Phase change materials have a solid consistency at room temperature. With the application of heat during first operation, the PCM flows to fill gaps and provide a thermal interface. With HP-PCM, the new Semikron Danfoss-exclusive High Performance Phase Change Material, we combine the benefits of a phase change material with the performance of the best available paste.

Key Features

- Best possible thermal performance

- Simplified logistics and reduced production costs

- Improved assembly robustness

- Increased lifetime and reliability

Portfolio

- HPTP: High Performance Thermal Paste

- HP-PCM: High Performance Phase Change Material