Motor Drives

Power Electronics for Motor Drives

Customer service

Product service

Performance Range

Since the first appearance of motor drives, Semikron Danfoss has been committed to supplying solutions for every power range. Almost 50 years ago, Semikron Danfoss introduced the first insulated power module: the SEMIPACK rectifier. Since then, other innovations for motor drives have been introduced, with the MiniSKiiP in particular revolutionizing the design of low and medium power systems.

Today, Semikron Danfoss offers the complete industry standard power module portfolio that serves a power range of 0.2kW to several megawatts.

With the latest generation of IGBTs and SiC MOSFETs from multiple suppliers, our power modules boost performance, power density, and effiency in motor drive applications.

The portfolio is completed with high power IPMs, power electronic stacks, and a comprehensive product line of driver electronics that help to reduce development effort and time-to-market.

- GENERAL PURPOSE DRIVES0.1kW to 300kWPumps, Fans, Compressors, Material handling, Conveyors, Marine drives, Factory automation

- CI, CIB, sixpacks, half-bridges

- Easy and cost effective assembly

- High power density for compact drive designs

- Wide power range packages for scalable platform design

- PERFORMANCE DRIVES0.1kW to 300kWLifts, Hoists, Spindle, Turbo applications, Single/multi-axis servo and motion control, Robotics controller, Extruders, Compressors

- CI, CIB, sixpacks, twelvepacks, half-bridges, IPMs, Single-PCB, multi-axis, drives and modular drive concepts

- High carrier frequency

- High overload/peak-load capability tolerance

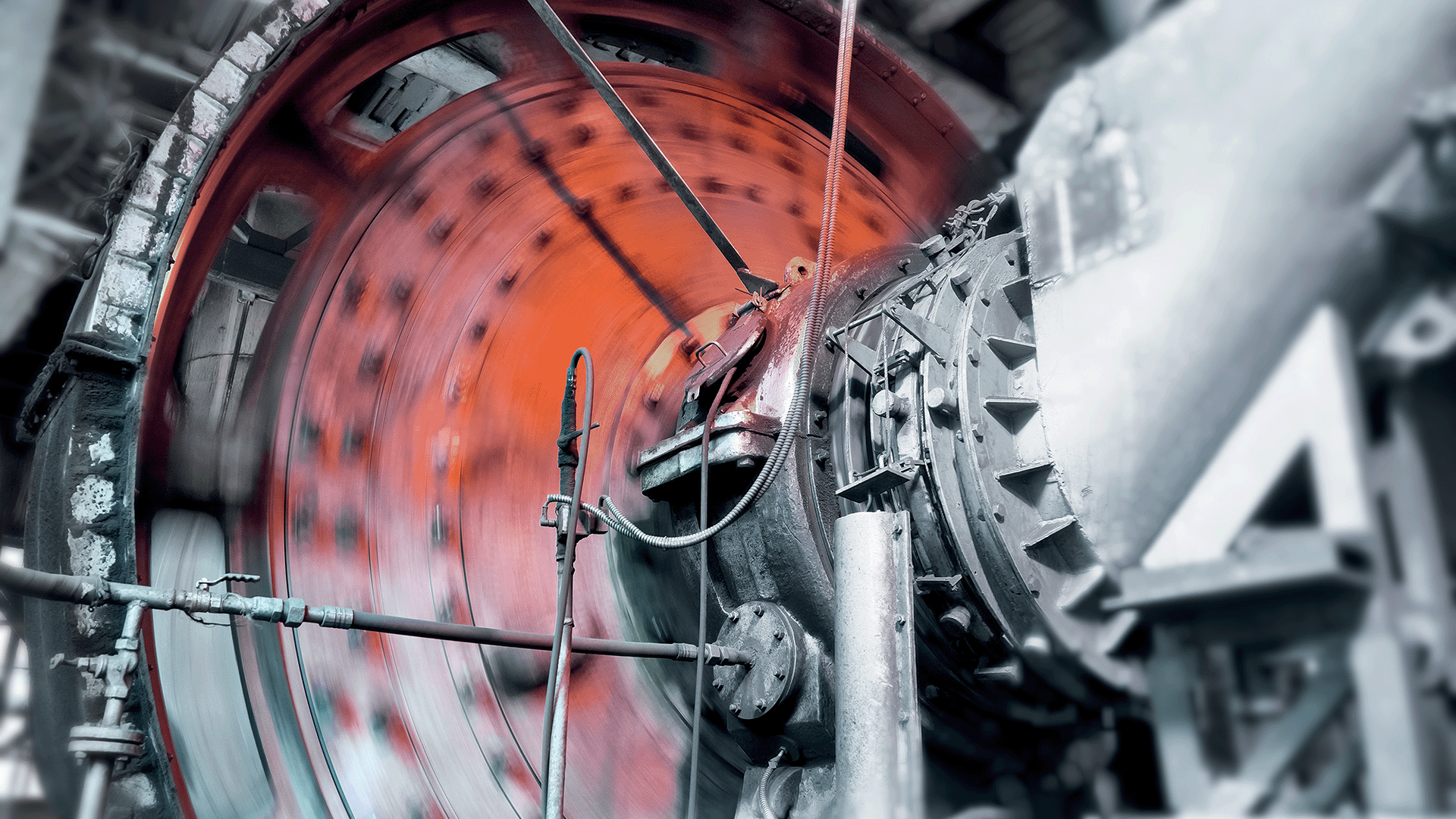

- HIGH POWER/MEDIUM VOLTAGE DRIVES300kW to 20MWPumps, Fans, Centrifuges, Mining, Marine drives, Pulp and paper

- Half-bridges, single switches, IPMs

- Compact designs with high power density

- High reliabily in harsh environments

Technology Highlights

Silicon Carbide MOSFETs for New Degrees of Freedom in Design

Compared to the latest generation Si IGBTS, the switching and conduction losses of SiC MOSFETs are considerably lower, thus offering designers new options for efficient drive platforms.

Increased power density allows for more compact drives or more power from given thermal designs. Faster switching with lower losses enables silent motor operation and smaller magnetics. Additionally, with SiC users can exploit new energy saving potentials. On a system level, this leads to a fast return on investment and reduced total cost of ownership. It also represents an important step towards more efficient energy utilization and decarbonization of the industry. Power modules with silicon carbide MOSFETs allow designers to push boundaries and re-think drives design.

With decades of experience in packaging power modules and supply chain reliabilty secured by strong, long-term partnerships with all top chip manufacturers, Semikron Danfoss is your ultimate partner for silicon carbide.

Silicon Carbide Features

- Greatly reduced conduction losses especially under partial load

- Lower switching losses by using the body diode as FWD

- Short circuit withstand capability of 2μs @800VDC/150°C

- in the latest generation of SiC MOSFET chips

- Highest power density and efficiency

- Robustness against ambient conditions

Applications

- Variable torque applications like fans, pumps

- Heat pumps

- Servo drives

Reliable Supply

- Multiple SiC chip sources

- Long-term partnerships with top SiC chip manufacturers

- More than 15 years of experience in packaging SiC

RGA IGBT for True Multiple Sourcing

With the ROHM RGA IGBT, a newly designed 1200V, trench gate, light punch through IGBT, we introduce a powerful alternative to current Generation 7 IGBTs.

The RGA IGBT, which was developed with motor drives in mind, is widely compatible to latest Generation 7 IGBTs. Likewise, it can be continuously operated at Tj,max=150°C and intermittently at Tj,max=175°C. Gate voltages are identical and the gate charge is even lower, thus it can easily be driven by existing driver circuits.

The RGA also offers advantages when comparing it to market available Generation 7 IGBTs. The chip size is optimized so that the thermal resistance is lower and a power module with RGA IGBT runs cooler. This allows for an increase of power or a reduction in cooling. Additionally, while typical Generation 7 IGBTs desaturate at twofold nominal current, the RGA IGBT can handle threefold nominal current, thus offering higher peak current tolerance.

With the ROHM RGA IGBT packed into our MiniSKiiP and SEMITOP E industry standard housings, there is now a true alternative to Generation 7 IGBT power modules.

Optimized for Motor Drives

- Low thermal resistant

- High peak current capability

- 1200V, 10 to 150A in CIB and sixpack topologies

Compatible with Market Standards

- Tj,max=175°C

- Robust against humidity

- Typical gate voltage -8 to +15VDC

- Industry standard packages

Reliable Supply

- Long-term partnership

- True multiple sourcing option from package down to chip

Product Highlights

Full Scalability for PCB-Based Designs

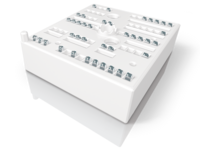

With two decades of field experience and more than 60 million modules in the field, the MiniSKiiP platform has proven successful in all standard applications.

The unique mechanical design offers the simplest possible assembly. Heatsink, module and PCB connected with one or two screws in a single step, making solder or press-in processes and tools obsolete. In terms of sensivity to mechanical or thermal stress, the springs doing the electrical connection between PCB and power module have proven to be far superior to solder or press-fit joints.

With its wide power range, the MiniSKiiP product family provides a unique base for scalable PCB-based drive designs from 0.4kW up to 110kW. With a variety of topologies, it is the perfect match from single-axis drives to single PCB assemblies with multple axes.

One Consistent Mounting Concept for Drives up to 110kW

- Available as CIB, sixpack, rectifier, brake chopper, twelvepack

- Covering 600/650V, 1200V, 1700V

Easy One-Step Mounting

- Easy PCB-based assembly with only one or two mounting screws

- High-productivity mounting thanks to automatable production lines

- No additional tools required, no soldering, no press-in process required

- Easy manufacturing of single-PCB multi-axis designs

Benchmark Performance

- Hybrid silicon carbide version offers highest efficiency and power density

- Lowest thermal resistance with High Performance Thermal Paste (HPTP)

- Spring contacts for superior vibration resistance

Flexibility for Compact Drives

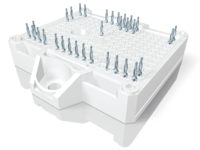

The SEMITOP E product line design offers a range of alternative packages for compact PCB-based motor drives. With multiple sourcing down to the chip level, it provides the best supply chain safety.

The baseplate-less design offers superior thermal performance. This, combined with a low-inductance design, also makes SEMITOP E the perfect package for the latest Si and SiC chip technologies.

SEMITOP E modules are available with pre-applied High Performance Thermal Paste (HPTP). Alternatively, for ease-of-handling during assembly, it can also be supplied with pre-applied HP-PCM, the new Semikron Danfoss-exclusive High Performance Phase Change Material.

Full Flexibility for Compact Drives

- CI, CIB, rectifiers with/without chopper, Sixpacks

- Covering 600V / 650V / 1200V: 10A to 200A

- Low inductance design ready for SiC

- Flexible pin-grid for additional topologies

- Press-fit or solder pins

Optimized Package

- 12mm high baseplate-less design

- Optimized press-fit pins for easier press in/out

Superior Thermal Performance

- Optimized DBC and pressure system for up to 20% lower Rth,j-s than market standard

- Available with pre-applied High Performance Thermal Paste (HPTP) or High Performance Phase Change Material (HP-PCM)

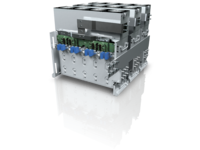

IGBT and Rectifier Module Family for Complete Motor Drive Solutions

SEMiX 3 Press-Fit features IGBT and rectifier modules in the same housing design for a complete medium/high power drive solution. As an industry standard power module available with the latest generation IGBT chips from different suppliers, it gives full supply chain safety.

It‘s your choice: SEMiX 3 Press-Fit is available with optional ...

... integrated current measurement shunts. The integration of the current measurement into the power module replaces expensive and bulky current sensors (i.e. Hall sensors). This reduces size and cost of the motor drive system.

... Plug-and-Play driver SKYPER 12 Press-Fit. Simply pressed onto the power module’s press-fit pins, the driver reduces time-to-market thanks to a ready-to-go solution.

... pre-applied phase change material HP-PCM. Combines the benefits of a phase change material with the performance of the best thermal paste.

Industry Standard Package with Optional:

- Integrated current shunts

- Plug-and-play gate driver

- Pre-applied phase change material

Available as a Complete 17mm-High Solution

- Rectifier, brake chopper and half-bridge

- 650V / 1200V / 1700V: 225A to 900A

- 55kW up to 350kW

- Full multiple source thanks to several IGBT suppliers

- Hybrid silicon carbide version offers highest efficiency and power density

The Latest Generation 7 IGBT

25% higher output power thanks to the latest Generation 7 IGBT

More about SEMiX 3 Press-Fit

Intelligent Power Modules – IPMs

For Maximum Reliability

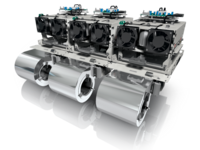

The SKiiP IPM product line sets a benchmark for high performance and robust inverter designs. Both SKiiP 3 and SKiiP 4 feature high power densities combined with flexible cooling options such as air and water cooling, also with customized heatsinks. Reliable driver technology, integrated current sensors and comprehensive protection functions complete the IPM design.

SKiiP 3 has propagated widely through the industrial drive segment. With its sixpack or half-bridge topologies, it covers a current range from 500A up to 2400A.

The SKiiP 4, available in half-bridge topology, has been optimized for highest power cycling requirements and covers the higher power range up to 3600A.

To ensure highest reliability and service life, the power circuitry is 100% solder-free. Sinter technology as die attach replaces the solder layer, which usually causes the limitation in lifetime.

Hence, sintering improves power and thermal cycling capability. The integrated gate driver in the SKiiP 4 has set new standards in terms of reliability and enhanced functionality through its CAN interface. The digital driver guarantees safe isolation between the primary and secondary side for both switching signals and parameter measurement. The CAN interface allows setting the SKiiP 4 configuration parameter and reading application parameter.

High Performance Cooling (HPC) technology has been introduced providing approximately 25% more output capability compared to standard water cooling. A double side mounting HPC water cooler is also available and enables an even higher power density.

Key Features

- 1200V and 1700V

- Half-bridge and sixpack

- 500A to 3600A

- Flexible cooling options: air, water or customized cooling options, high performance cooling, single and double side mounting water coolers

- Paralleled operation for even higher output power possible

Power Electronic Stack Platforms

Fully Qualified Inverter Assemblies Tailored to Your Specific Needs

Standard Stacks

Our Power Electronic Stacks enable our customers to succeed in dynamic markets and meet any global challenge. We deliver Rectifier-, IGBT- and SiC-based stacks for AC voltages from 380V to 690V. Our standard stacks cover an output current range from 70A to 4000A.

- Water-Cooled IGBT Stacks

SKiiPRACK

SEMISTACK RE - Air-Cooled IGBT Stacks

SEMIKUBE

SEMIKUBE SlimLine - Diode/Thyristor Stacks

SEMISTACK CLASSIC B6U/B6C/W3C

Customized Stacks

In addition to standard stacks, Semikron Danfoss has vast experience in developing customer-specific solutions. Engineers are available in our stack centers around the globe to offer specific solutions by adapting existing platforms or designing customized converters.

Four Key Factors for your success

- Shortest time to market

- Cost savings in R&D, production and qualification

- Global SEMIKRON Danfoss stack production footprint

- Highly experienced engineering team

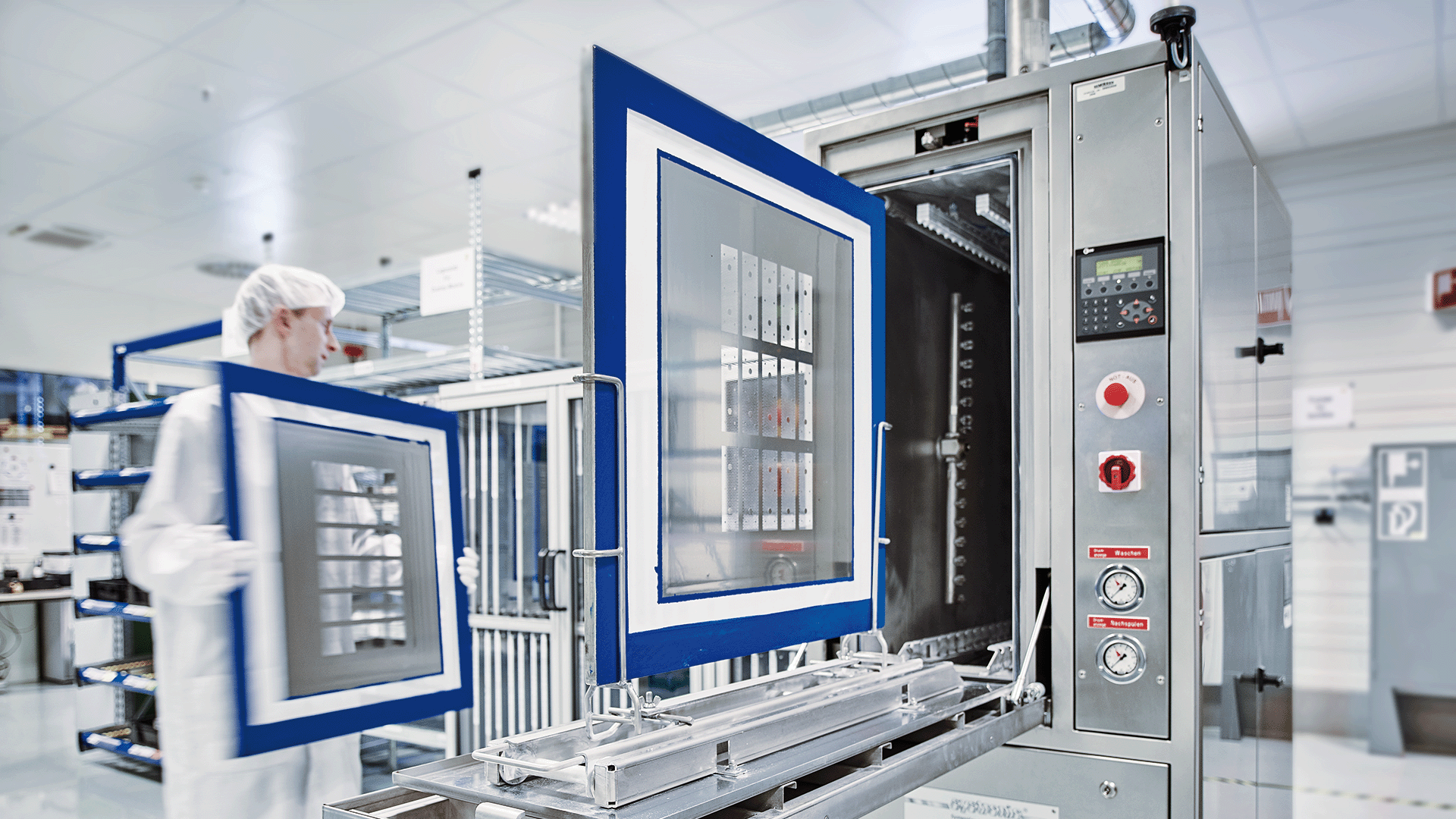

Thermal Interface Materials

Stay Cool – Heat Dissipation is Our Job

Semikron Danfoss was the first power module manufacturer on the market to offer power modules with pre-applied thermal interface material (TIM). We now have over two decades of experience and more than 25 million pre-printed modules in the field.

We design print patterns for each module type for the best TIM distribution and thickness when the module is mounted to a heatsink. These patterns are printed on the modules in a clean environment on an automated silkscreen and stencil printing line. Statistical process control (SPC) is used to guarantee consistency. Special packaging is implemented to ensure that the TIM arrives at your production line in pristine condition.

In order to achieve the best thermal performance in all applications, Semikron Danfoss power modules can be supplied with our High Performance Thermal Paste (HPTP).

Alternatively, for ease-of-handling during assembly, most power modules are also available with pre-applied phase change material (PCM). Phase change materials have a solid consistency at room temperature. With the application of heat during first operation, the PCM flows to fill gaps and provide a thermal in- terface. With HP-PCM, the new Semikron Danfoss-exclusive High Performance Phase Change Material, we combine the benefits of a phase change material with the performance of the best available paste.

Key Features

- Best possible thermal performance

- Simplified logistics and reduced production costs

- Improved assembly robustness

- Increased lifetime and reliability

Portfolio

- HPTP: High Performance Thermal Paste

- HP-PCM: High Performance Phase Change Material