E-Mobility and Utility Electric Vehicles

Power Electronics

Customer service

Product service

Utility Electric Vehicles

The utility electric vehicles segment today comprises primarely the traditional material handling market where battery operated vehicles like fork-lifts have been well established for decades. Semikron Danfoss has been serving this market for more than 20 years and offers complete SKAI inverter systems for low voltages as well as for voltages of 800VDC.

The electrification of vehicles in the agriculture and construction sector, in contrast, is still in its infancy. There is, however, substantial potential for this area to grow in the future thanks to the cost benefits of battery driven functions. SKiM 93 power modules are the ideal choice for traction drives, while our SKAI HV inverters, which can incorporate auxiliary functions as well, are suitable for higher integration levels. The utility vehicle segment typically relies on industrial standard products.

E-Mobility

The e-mobility segment includes passenger cars as well as medium/heavy duty buses and trucks and light electric vehicles. This market is driven by statutory CO2 emissions limits and the components and systems used in e-mobility applications must comply with automotive standards. Compactness and inverter efficiency are the key to reducing energy consumption in electric vehicles. The high-volume passenger car segment is the fastest growing e-mobility market.

Semikron Danfoss adresses this market with dedicated modules for traction drives - the DCM and the eMPack. For the bus and truck market, Semikron Danfoss also offers complete SKAI inverter systems. The light electric vehicle market, a highly fragmented market with power ranges of up to around 40kW, includes two-wheelers, small delivery trucks, recreational / neighborhood vehicles and many more smaller, yet fast growing niches. SKAI LV is the dedicated product for these applications.

Product Highlights

Power Module Platform

In passenger car applications, power electronics have to rise to considerable challenges: they have to be compact and efficient, while remaining robust and reliable under the changing conditions that occur during cold start and repeated acceleration and deceleration. Semikron Danfoss offers a wide range of products that rise to the occasion in any application in the automotive sector, be it battery-powered electric vehicles, mild hybrids, plug-in hybrids or other hybrid drive vehicles.

Our dedicated automotive portfolio includes power modules and integrated converter/inverter systems that are often based on innovative semiconductor technologies such as silicon carbide (SiC), significantly improving efficiency in standard passenger vehicle applications in comparison to silicon-based technology (IGBTs).

The transition of complete car platforms to full electric battery vehicle architectures is progressing rapidly. These architectures will demand scalable power electronics solutions for electric drive systems (EDS) that are capable of realizing a wide performance range in an economic way, resulting in competitive advantage to vehicle manufacturers.

Semikron Danfoss’ new power module platform eMPack, which is based on a common module concept, is being developed for EDS inverter architectures covering a power range from 100kW up to 750kW. eMPack covers 400V and 800V battery system applications.

The combination of Silicon Carbide technology with our fully sintered, low stray inductance Direct Pressed Die Technology (DPD) enables unmatched power densities combined with high reliability for automotive application.

Product Features

- High efficiency SiC technology

- Ultra-low stray inductance

- Superior reliability in a fully sintered package

- Dedicated configurations for all BEV power ranges

- Compact package

Power Module Platform

To power up the fast-growing fleet of HEVs, PHEVs and BEVs, Semikron Danfoss has developed a power module technology platform, DCMTM, for traction applications. With silicon (Si) and silicon carbide (SiC) being the main cost-drivers in power modules, our DCMTM technology platform aims at reducing the semiconductor surface enabled by combining patented technologies.

At the same time, the DCMTM also increases power density, reliability, robustness and lifetime of the inverter. By selecting the best fitting chips from a competitive supplier base and by carefully selecting the power module components, package and electrical configuration, we are able to use the semiconductors to their full potential.

The DCMTM technology platform is designed to be scalable. In the same package, we can scale the power up or down to meet different inverter voltage classes with blocking voltages of 750V-1200V, while having different output currents from 350 to 900A.

Furthermore, our power modules are based on quality components, patented packaging and cooling technologies to achieve outstanding, measurable results in terms of reliable performance and robustness – all adding up to ensure a cost-effective solution that lasts.

Our certified processes assure for consistent high quality and streamlined path from development to volume manufacturing.

Product Features

- Highest flexibility in design, customized interfaces

- Scalable across voltage classes

- Advanced bonding technologies for highest power cycling robustness

- High power density

- Robust molded module packaging

- Direct liquid cooling with ShowerPower 3D

Ultra Compact MOSFET Inverter Platform

More and more utility vehicles such as forklift trucks now run on electric power. In fact, what was once state of the art for indoor vehicles, is now increasingly finding its way into outdoor vehicles, as powertrain electrification continues to advance and enter new vehicular applications. Today, power electronic systems are as commonplace in motorbikes, quads and other light electric vehicles as they are in agricultural and construction vehicles.

The SKAI LV converter/inverter system is a platform solution that is designed for use in combination with existing or optimised controller systems, enabling the quick development of optimised, cost-efficient custom solutions for utility and light electric vehicles. The compact design of the SKAI LV makes it the right fit for use in industrial forklift trucks as well as in other industrial or road vehicles.

The SKAI LV is a platform for low-voltage inverter systems for on- and off-road applications. This platform constitutes the 3rd generation of low-voltage inverter systems and the 7th gene- ration of MOSFET inverter technology developed by Semikron Danfoss, with more than 1.5 million MOSFET inverters in the field.

To create an optimized application-specific motor control system, simply integrate a customized control board. The SKAI LV platform is based on the same power-technology found in high-voltage, high-reliability applications today, providing access to high-power, maximum reliability technologies across a wide range of low-voltage on and off-road applications.

Product Features

- Voltage, current and temperature sensors

- Gate driver with protection

- Low inductance, low loss power section

- DC link capacitors

- Air and plate cooling

- Easy-to-use gate driver interface

- Platform for customised designs

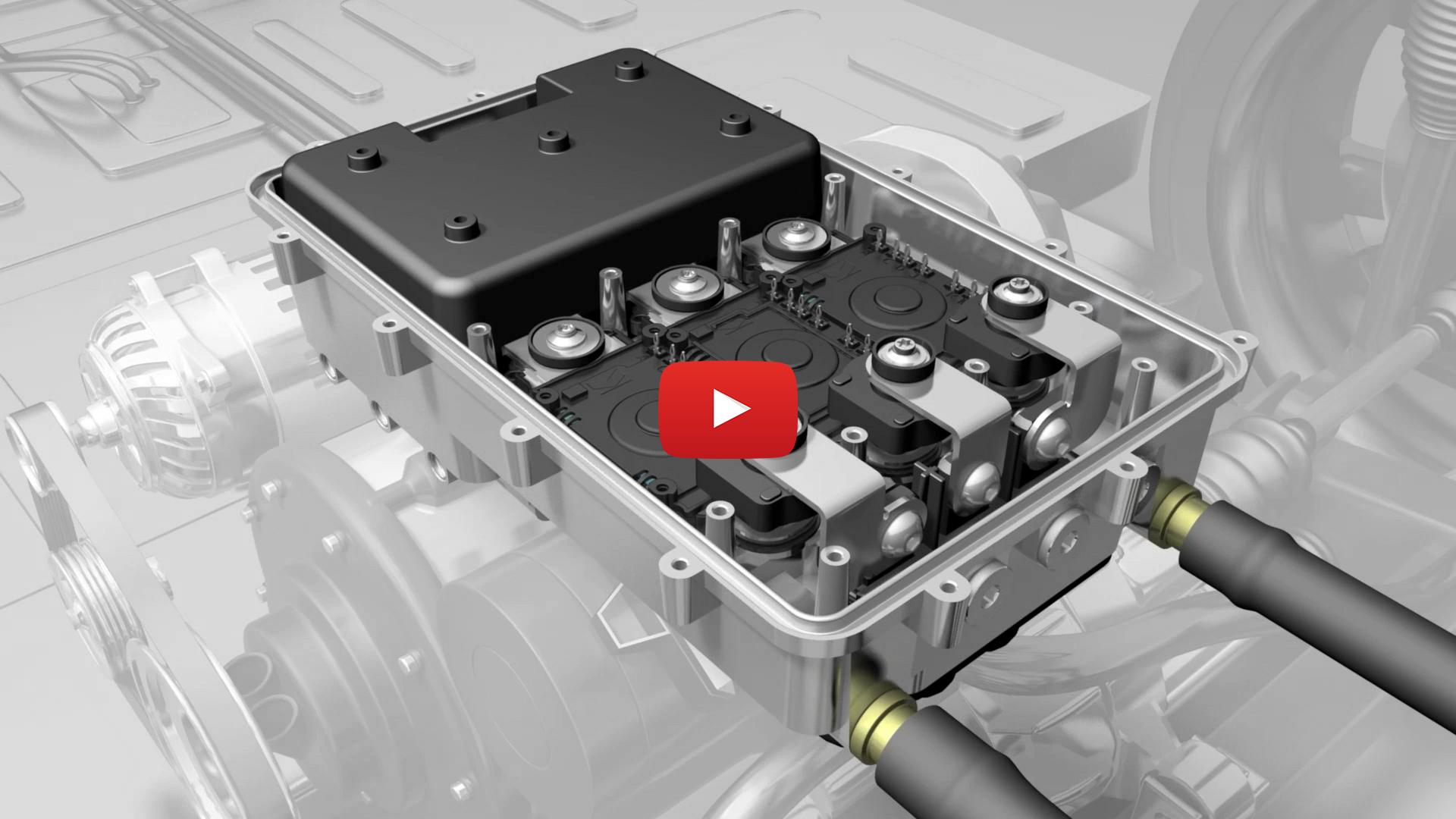

Compact Power Electronic System

Hybrid electric or all-electric buses are already in widespread use in our cities today and are an effective way of reducing pollutant emissions or avoiding them altogether. This move towards cleaner mobility is also being seen in trucks, with more and more manufacturers introducing hybrid electric or all-electric trucks to their fleets.

In heavy-duty off-road utility vehicles such as construction site vehicles and agricultural machinery, the power electronics are exposed to particularly harsh ambient conditions. They have to be ultra-compact and lightweight, while exhibiting good vibration, impact and shock resistance in order for them to work reliably on uneven terrain. They have to be able to work at both very low and very high ambient and coolant temperatures and boast excellent thermal and power cycling capabilities at the same time.

SKAI HV comprises a versatile 3-phase converter platform designed for use in electrified vehicles. It covers key requirements such as high power density, exceptional ruggedness and automotive EMI compliance. The integrated motor control software SKAIware ensures highly efficient operation of the

electric drive train.

The SKAI HV power electronic platform comprises highly integrated motor controllers, which provide the ideal powertrain solution for mobile electric and hybrid applications. Power densities of up to 24kVA/litre bring notable size reductions compared with other existing standard motor controller products. The systems are designed to operate with supply voltages of up to 800VDC and with output power ratings of up to 300kVA. The IGBT based SKAI HV motor controller operates on sintered, 100% solder free 1200V power semiconductors and features polypropylene film DC-link capacitors, all integrated into a waterproof IP67 enclosure. The compact motor controllers can withstand high vibration amplitudes of up to 10gRMS.

SKAIware motor control software adds to the system function and completes off this tried-and-tested package for the SKAI HV nicely. Semikron Danfoss provides engineering services to support customers with the integration of SKAI HV motor controller systems. Other available services include lifetime estimation, field application support, individual parameterization of motor control software, and more.

Product Features

- Compact integration into IP67 enclosure

- Voltage, current and temperature sensors

- Gate driver with protection

- IGBT power semiconductors

- Fully programmable digital signal processor

- EMI filters

- Versatile cooling system (liquid cooled, forced air cooled, base plate)

- DC-link capacitors

- Motor control software

Service

Helping Your Business Use Our Products

Application Expertise is our Strength

Being able to access service, technical support and experts that our customers can always rely on is instrumental to our customers’ success. Today, increased product diversity in power semiconductors calls for customer support far beyond the information contained in data sheets. Only comparison under application-specific conditions – such as voltage, switching frequency or cooling conditions – can demonstrate the differences in performance of available devices. That’s why we continue to invest in our professional application engineering support, including lab space and reference designs.

Customize your Power Solution

Besides standard configurations, Semikron Danfoss also offers customer specific topologies in various housings, addressing the market need for innovation and differentiation. It allows us to provide an unmatches flexibility in power module designs. Our highly skilled and specialized engineers at Semikron Danfoss work closely with you to design power modules for your specific drivetrain design, allowing you to scale your power solution according to your specifications.

In recent years, we have built a network comprising 24 sites across the globe to provide fast, comprehensive application support. Our application engineering teams work with our customers both locally and globally. throughout the entire project life cycle. We strive to understand and help our customers overcome both big and small challenges throughout their projects. For example, we conduct topology studies to fully understand the advantages in the end user application and carry out benchmark investigations when needed. It is this application-centred approach that sets us apart from others.

How can Semikron Danfoss help you with Inverter Design?

- Application and performance calculations

- DC link design and capacitor selection

- Isolation coordination

- Lifetime calculations

- Measurement support

- Application samples and reference designs